Why our clients love us

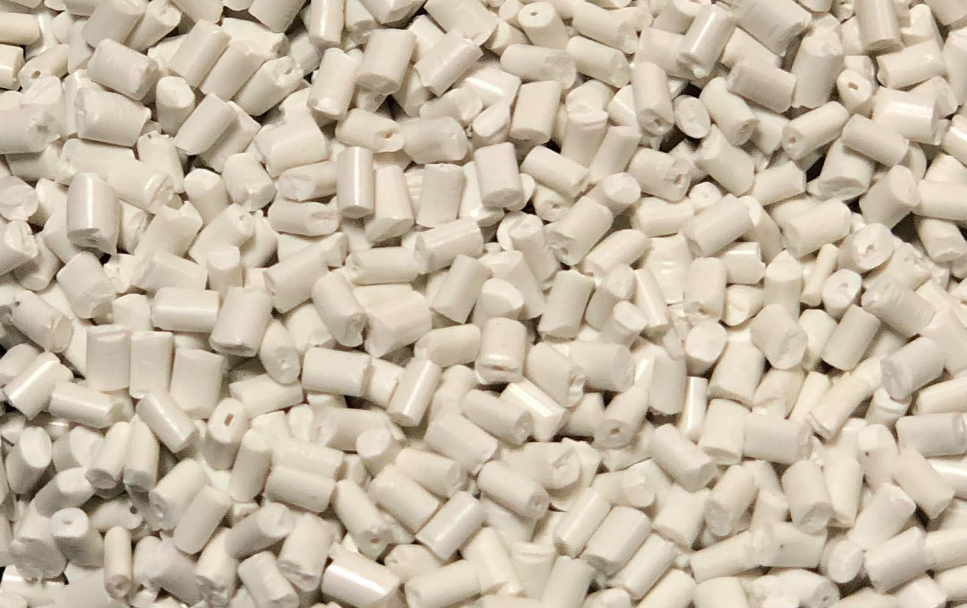

Our granules and regrinds are imported and manufactured at the highest quality and efficiency as we keep pushing the standards for polymer manufacturing in India.

With one of the most efficient and well managed manufacturing plants in the country, it is our longstanding aim to produce the finest quality products right on schedule, as promised.

Every order placed, no matter the size is passionately taken care of by our professionals with the same certainty and to bring the finest quality. Your orders don’t surprise us, they excite us!

Our R&D team is constantly increasing in size, quality and efficiency. We are one of the few reprocessed granule manufacturers who are regularly investing in R&D.

What do we do?

source

source

We procure industrial scrap and articles from scratch with the use of our world class facilities designed for you to get only the best final product. We also import regrind materials so that we can support our mission to being a sustainable and eco-friendly polymer manufacturer in India.

MANUFACTURING & JOBWORK

MANUFACTURING & JOBWORK

Each of our clients have different and specific needs and we’re all about providing the best for every one of them. Our polymer manufacturing plants along with our industry professionals are compatible to adapt their skillsets to match our client’s needs.

Trading

Trading

We’ve partnered with industry stalwarts like Reliance, Opel, GAIL India, HALDIYA, ABSOLAC and many more to trade prime materials and Off Grade Materials.

RESEARCH & DEVELOPMENT

RESEARCH & DEVELOPMENT

- Currently, we’re following these reports:

- i. Melt Flow Index : Melt Flow Index (MFI) is a measure of how many grams of a polymer flow through the die in ten minutes. We’re constantly monitoring the stats from these reports in a bid to be as efficient as humanly possible.

- ii. Notched Impact Strength : This report tells us volumes about the strength of our raw materials which help us specifically deliver the final product to our clientele.

- iii. Tensile Report : The tensile test measures the resistant of a material to the given static load. The results that generated from the tensile test shows the mechanical properties of our raw materials so that we can make the best use of the precious offerings from the environment.

- iv. Ashed Content : Ash content represents the incombustible component remaining after a sample of the furnace oil is completely burned. This enables us to make the most use of our raw materials and repurpose the remains so as to try and achieve 100%